Powered by paramate

Fixture design, simplified.

Design custom fixtures in under 20 minutes.

CAD expertise is optional.

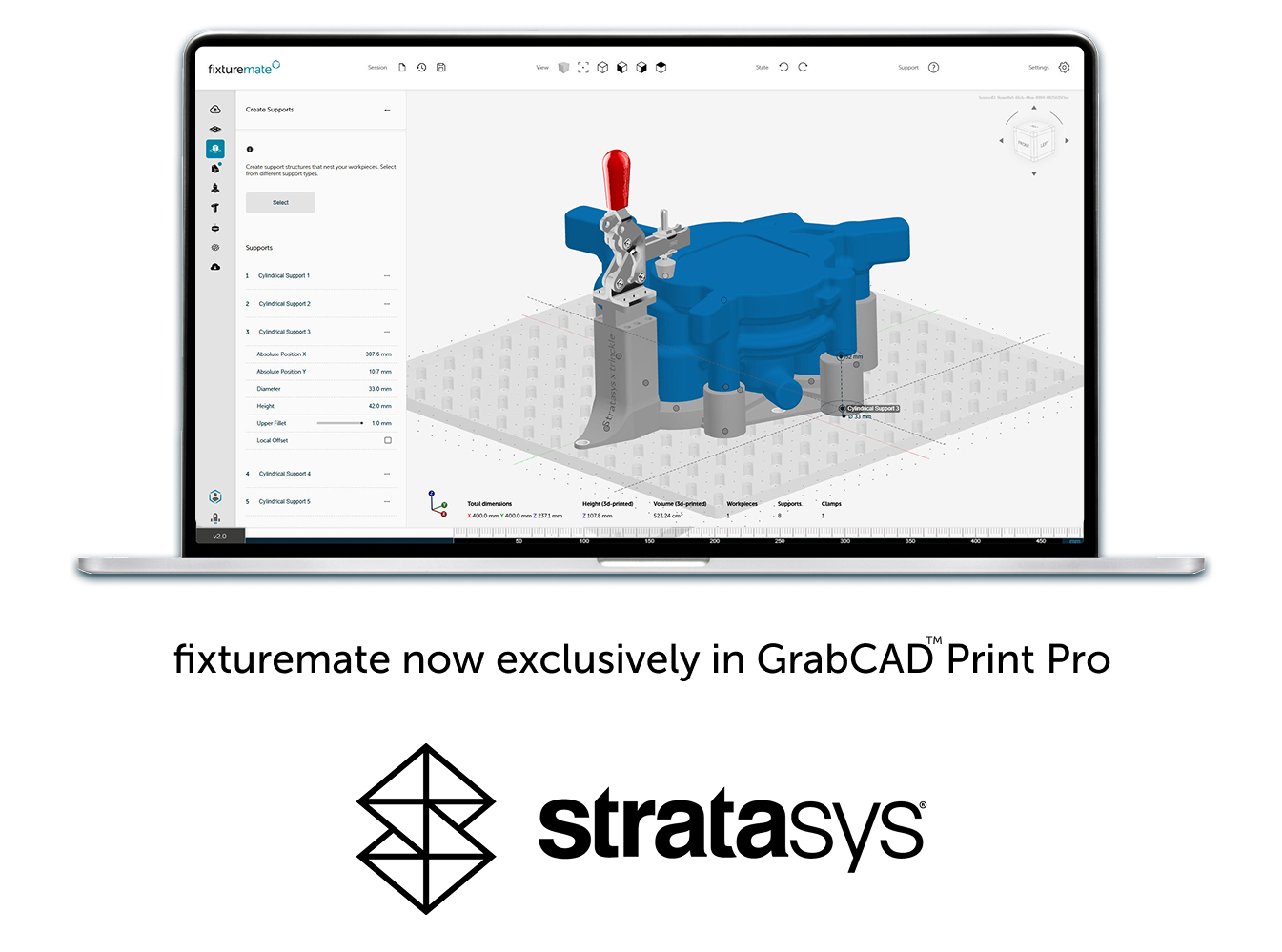

fixturemate is now integrated with GrabCAD Print™ Pro from Stratasys

Design without CAD complexity

Fixture design in CAD software is time consuming – even for experienced engineers.

fixturemate is intuitive web-based software that allows anyone

to design fixtures fast, whether you're familiar with CAD or not.

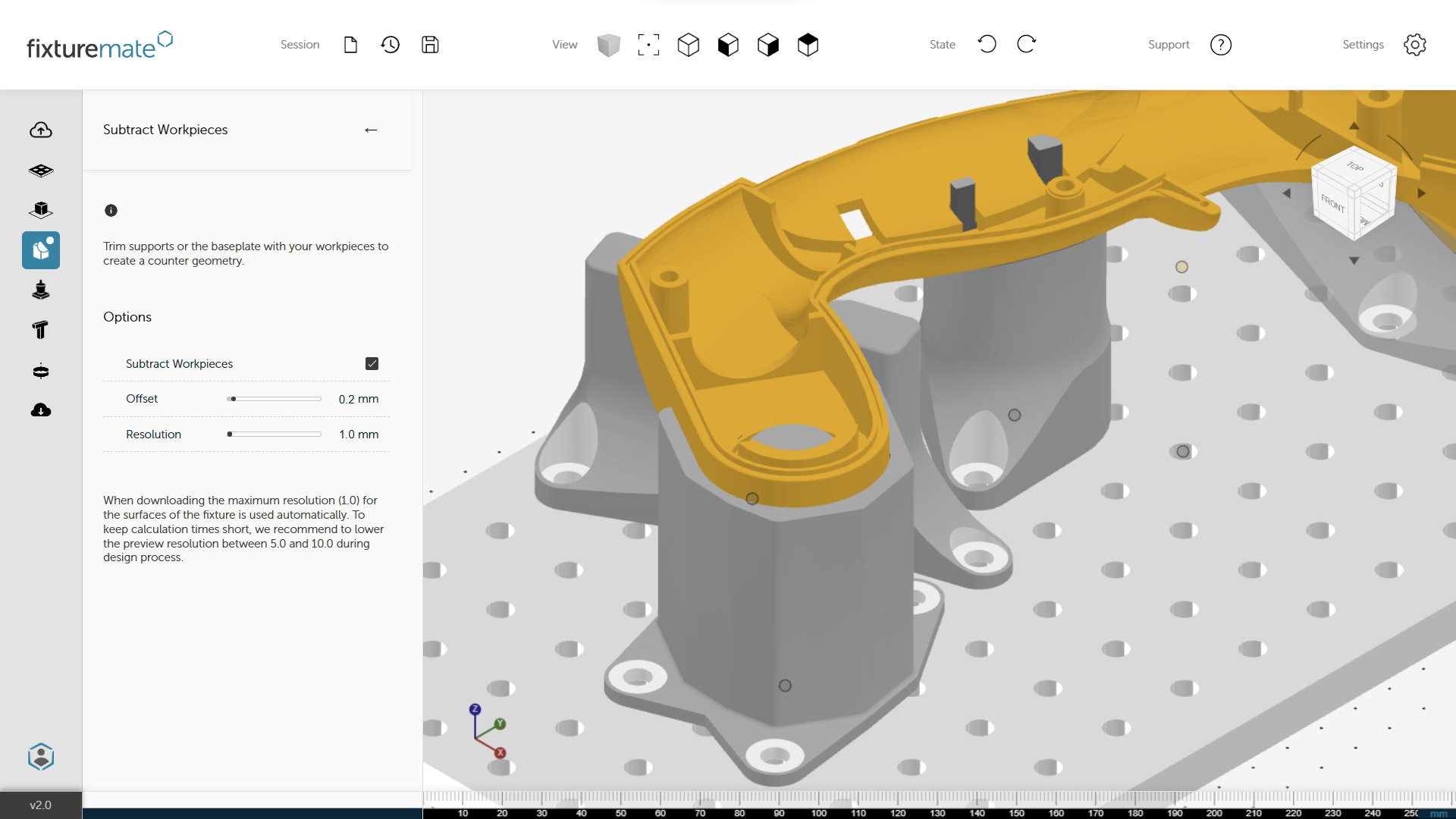

Easily create a negative

In just a few clicks, subtract complex geometries, avoid undercuts, and fine-tune offsets for a securely fitted fixture.

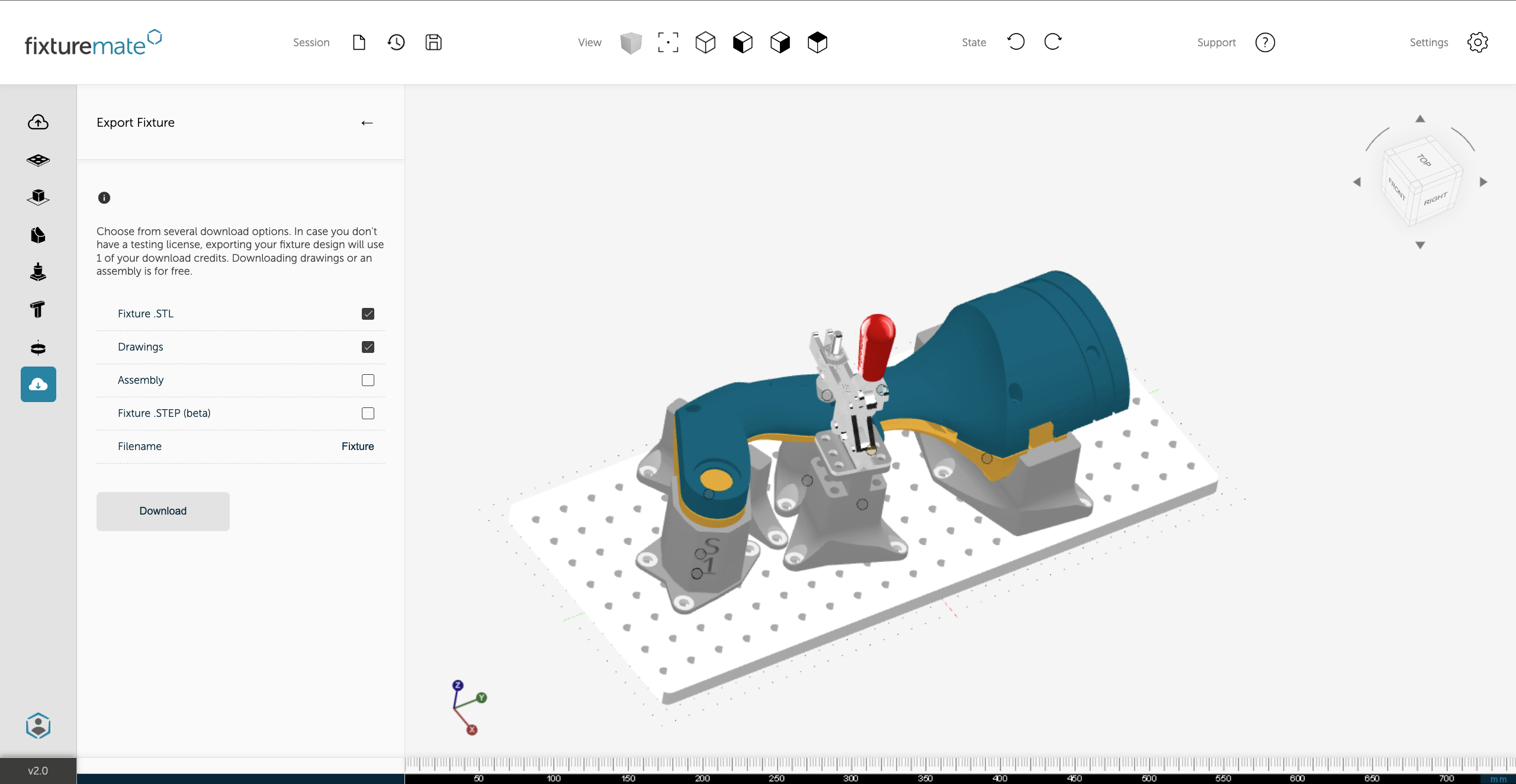

Seamless 3D printing integration

Exports are optimized for 3D printing, so once your design is complete, simply slice, 3D print, and deploy your custom fixture within hours.

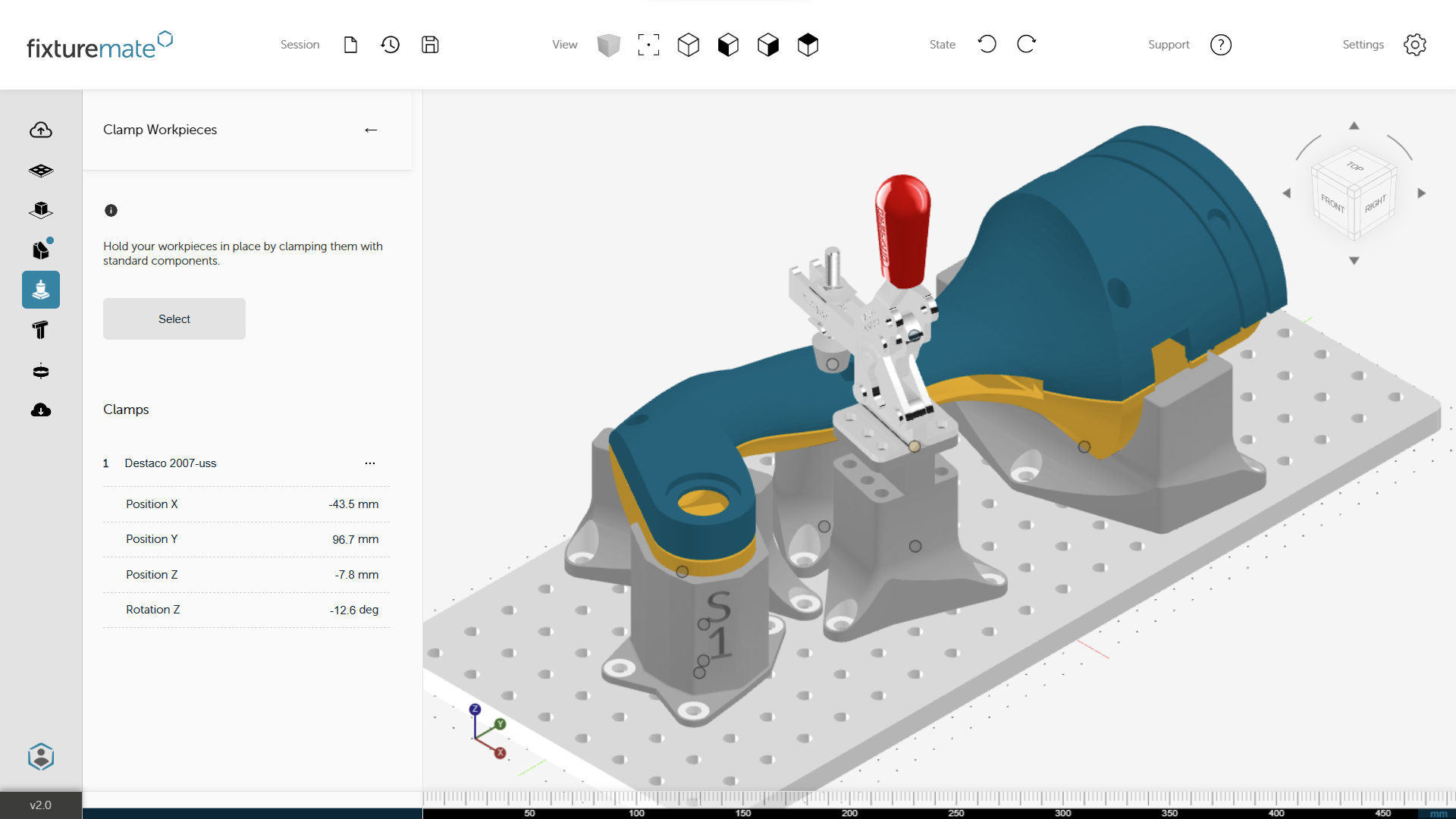

Industry-standard components included

A range of standard clamps and baseplates are available directly in fixturemate, saving you the hassle of creating these components from scratch.

How our customers rethink fixtures

"In CAD we usually need two to four hours to produce a design, depending on the size of the part. With fixturemate we can produce a usable fixture in minutes."

"trinckle's fixturemate software has seamlessly integrated design automation into our additive manufacturing processes for tooling at Deutsche Bahn. The software has drastically reduced our design times and costs."

One software, multiple applications

fixturemate is already being used by industry to create a

diverse range of 3D printed production aids and tooling, including:

Assembly fixtures

Streamline assembly with exact part orientation for simple connections and mounting.

Learn more

Welding fixtures

Ensure precise alignment and stability when bonding or welding parts, guaranteeing consistency.

Learn moreInspection gauges

Use Go/No-go gauges to swiftly check the accuracy of parts after production or assembly.

Learn more

Machining fixtures

Create strong and stable custom workholdings for turning, drilling, and milling operations.

Learn more